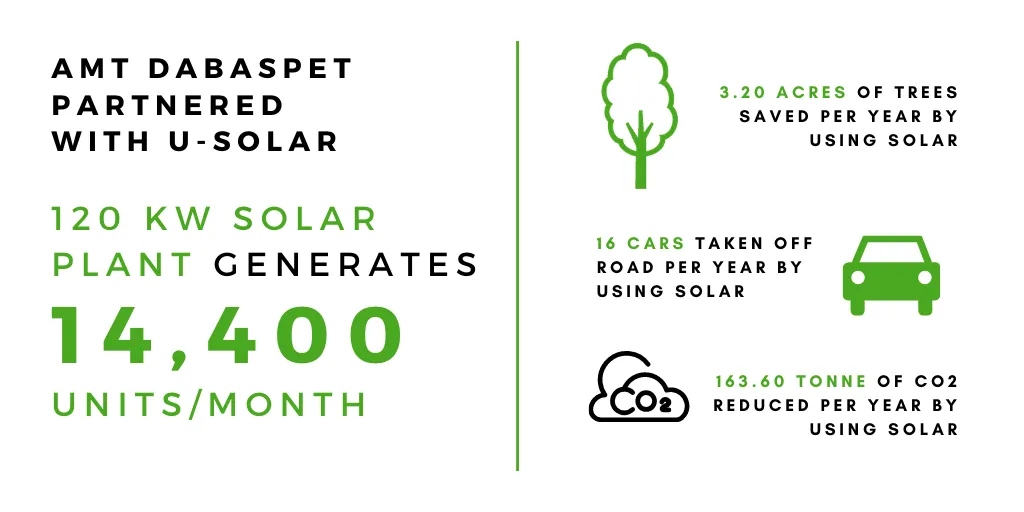

Advance Mould Technology India is a copper molding company that has been operating since 2010. It is a proud subsidiary of the KME group and Mishima Kosan Co Ltd. Japan. The company’s principal offering is copper molding and it’s reconditioning to supply value-added services to the steel industry in India. The energy consumption within the copper industry has been extensive over the years. Reducing the overall maintenance cost of the plant was on AMT’s agenda as part of its continuous improvement cycle. Thus, these copper molding giants were motivated towards solar energy to accentuate their effort toward financial profitability & environmental sustainability. To achieve this, the company has installed the rooftop solar power plant of 120 KW capacity for its facility at Dabaspet, Karnataka.

The solar power plant was set up in the 2 phases. The capacity of the solar plant is divided in 2 phases; 65 & 55 KW. The solar power plant has been constructed on a sheet roof with a premium quality 320 kWp polycrystalline solar PV module by RISEN. Total of 375 modules have been used. 5 nos. of 25 kW SMA solar inverters complete the technical setup for the solar power plant. The O&M associated with the plant has been commissioned to U-Solar for 5 years since the date of project completion. Safety guidelines necessary for a sheet roof plant were check-listed by U-Solar by installing lifelines and walkways, according to the required standards.

The company has opted for CAPEX model; direct ownership of plant from Day 1. The plant will run on clean energy for a lifetime. Karnataka ranks number 1 in the State Rooftop Solar Attractiveness Index (SARAL), which was launched by Power Minister RK Singh in 2019. Search Results

Karnataka shows good potential for solar, getting an average insolation for more than 5 kWh/m2/day, having about 300-330 clear sunny days. The state attracts rooftop solar development due to certain key aspects like the robustness of policy framework, implementation environment, and business ecosystem.

The solar power plant generation is approximately 1,00,000 units per annum offsetting the facility’s total energy consumption. Savings worth Rs. 6,oo,ooo per year have been generated & CO2 footprint has reduced significantly since the solar power plant has been commissioned in 2016. The corporate’s commitment towards curbing the environmental impact of its factories and the promotion of socially moral initiatives is sure to benchmark a positive impression within the molding industry for pursuing sustainable growth.

__________________________

If your organization is looking to adopt solar, please feel free to get in touch with us. We believe in partnering with our clients on their sustainability journey.

Email us at info@usolar.in

WhatsApp us at +91 63 6622 6970 | https://wa.me/916366236970